Modular Intralogistics with Decentralized Automation Solutions

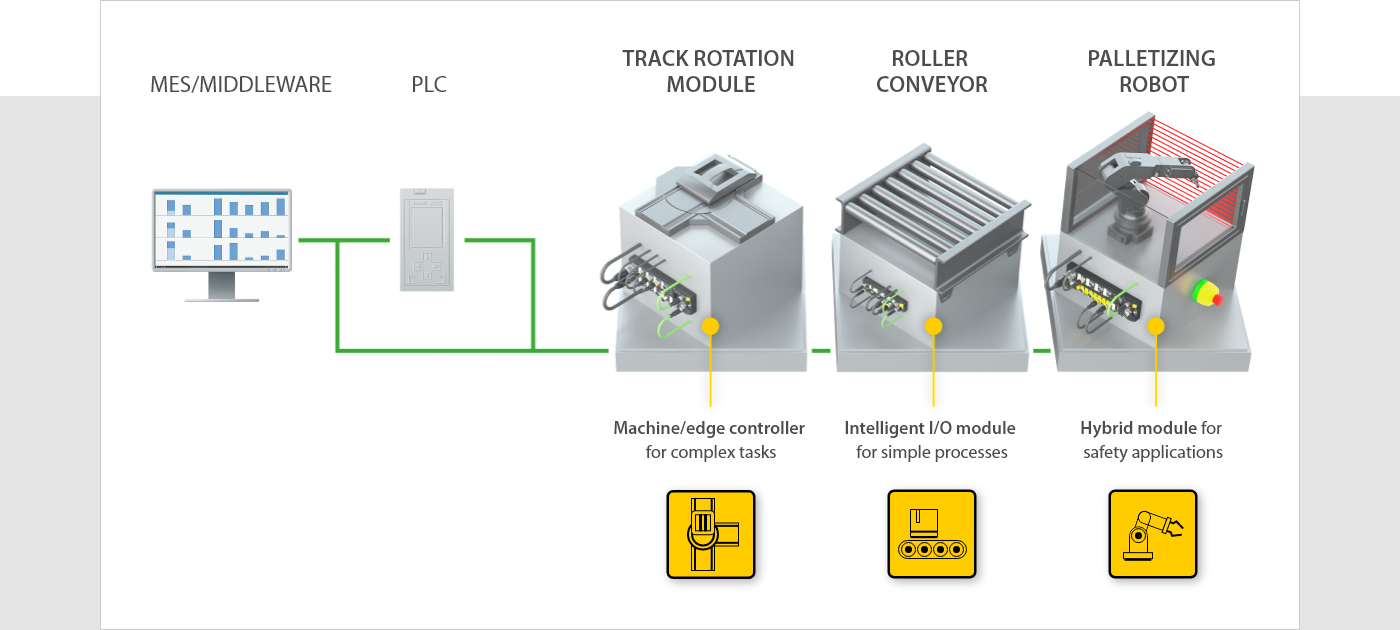

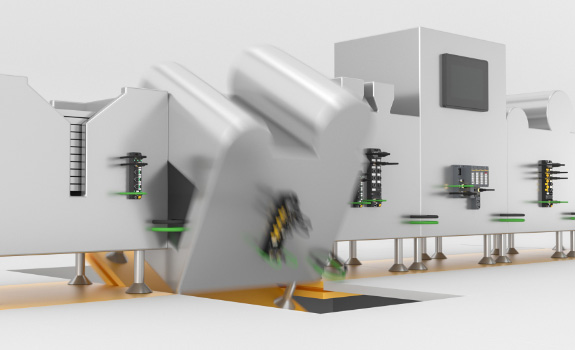

Digitalization, artificial intelligence and, of course, the growth of e-commerce are the driving forces behind brand new innovations in internal logistics. Fully automated transport management systems deliver materials to their destination autonomously and efficiently — whether they are used in production, picking or dispatching applications. Machine modules with decentralized control logic make this possible. By transferring the required intelligence straight to the conveyor system environment, they enable improvements such as significantly reducing time-to-market for new plants.

Modular Principle Instead of Static Lines

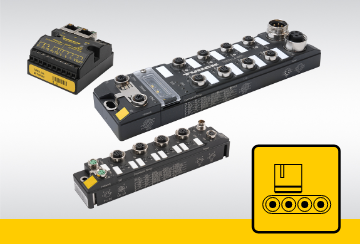

Turck's compact IP67 edge controllers or block I/O modules enable decentralized control of logistics plant processes. If necessary, the autonomous modules can still communicate with a main control system thanks to the use of multiprotocol Ethernet via Profinet, Ethernet/IP or Modbus TCP

Edge Controller — complex control tasks

Decentralized control instead of top-down management: In a smart conveyor system that comprises autonomous transport modules, Turck's TBEN-L-PLC Codesys-3 controllers each coordinate an entire subsystem. The modules are interconnected via Ethernet UDP and function using swarm intelligence. Due to its wide range of interfaces, the compact PLC can be integrated into different networks as a master or slave. As an edge controller, the PLC can pre-process data and selectively transfer it to higher-level systems such as MES, ERP or a cloud, thus enabling effective condition monitoring on mobile devices.

Standard fieldbus module — independently process sub-functions

The ARGEE free programming interface allows users to utilize the full potential of Turck's standard fieldbus modules and therefore process small to medium-level control tasks. For example, when used on a roller conveyor, an I/O module can control the interaction between a photoelectric sensor and the roller movement. This arrangement helps users to prevent transported materials being damaged by heavy impacts. If required, data can flow directly into the MES without a detour through a higher-level PLC, for example via Modbus TCP.

Hybrid safety module — independent safety control

Even safety functions can be controlled via safety I/O modules positioned in the immediate vicinity of the hazardous area. Decentralized signal processing allows shorter cycle times to achieve a potentially higher conveyor speed. In addition, the safety functions in unaffected parts of the plant are retained when unplanned events occur, such as a cable break. Users configure the safety functions of the safety I/O modules using the versatile Turck Safety Configurator.

Webinar – How to Control Variable Conveyor Systems in the Field

Reap the Benefits of Modular Automation

Short time-to-market

- Fast delivery thanks to the modular principle

- Test machine modules offline first

- Reuse existing modules

- Respond dynamically to new requirements

Fast commissioning

- Easy wiring thanks to IP67 components and quick connectors

- In-house wiring and module testing reduce on-site installation times

- Flexible combination of machine modules

Low costs

- Reduced hardware requirements since control cabinets or controllers are not required

- Reduced wiring costs due to IP67 I/O systems used directly in the field

- Reduced labor costs during commissioning

- Reduction in the necessary control capacities, enabling more data to be processed with fewer IP addresses

High performance

- Load on the main controller is reduced since functions are outsourced

- Reduced data exchange with the central PLC enables shorter cycle times and faster process speeds

- More capacity for logic calculations due to the reduced number of network connections

Whitepaper: Modular Plant Designs with Decentralized Automation

Learn more about the importance of decentralized machine units, communication standards and the right hardware and software solutions for designing modular systems

Block by Block — Modular Intralogistics in Practice

Explore some examples of successful intralogistics applications and discover the benefits of modular plant design for yourself

The Right Product Solution for Your Application

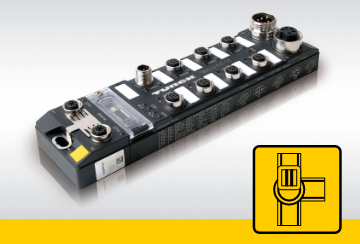

Compact IP67 edge controller with Codesys

Benefit from the wide range of interfaces and the robustness of the TBEN-PLC. PLCs with Codesys are particularly suitable for modular machines because the open control software enables various subsystems to be connected together and enhanced with intelligent features.

I/O modules with logical control function

Turck's I/O modules with multiprotocol Ethernet are equipped with logical control capability at the factory. Control functions are implemented on the module and executed via the module using the HTML5- or JavaScript-based ARGEE interface. Everything from simple configuration tasks to complex programming can be performed at no additional cost.

Safety modules with integrated safety controller

IP67 block I/Os enable safety functions to be implemented without control cabinets. The integrated safety controller can be used to configure the I/O modules via a PC. Safety applications can be tested offline and controlled decentrally in live operation.

IO-Link products

Turck's IO-Link portfolio is impressively comprehensive. As a full provider of both the device and the master side, Turck guarantees easy integration of IO-Link devices into the control environment.

Programmable HMIs

If users require more than just control functions and need information to be visualized directly on the machine and commands to be entered, HMI operator panels are the ideal solution. The TX100, 500 and 700 series offer numerous interfaces. And there are no extra costs for licenses of the visualization software.

Reduced number of IP addresses thanks to Beep

Turck's Backplane Ethernet Extension Protocol—or BEEP for short—connects networks with up to 33 TBEN modules (1 master, 32 slaves) and up to 480 bytes of data to the PLC via a single IP address in Profinet, EtherNet/IP and Modbus TCP networks.

Tell us About your Project

Would you like to learn more about automation solutions for modular intralogistics? Simply contact our experts — we will be happy to advise you personally

Aurel Buda