Decentralized Automation in Ex Areas

The Ex approval of the IP67 I/O series TBEN-S and TBEN-L enables us to implement more decentralized solutions throughout, even in Ex environments

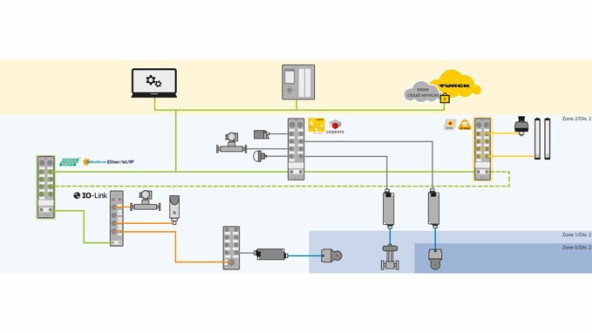

The benefits of decentralized automation are winning over more and more users in machine and plant construction. Decentralized solutions offer advantages in terms of flexibility and time-to-market, especially in the design and engineering of modular machine concepts, thanks to factory acceptance tests in standalone mode. The benefits can now also be reaped in Ex areas.

Connecting intrinsically safe signals in Zone 2 without a cabinet

Turck offers an integrated IP67 system for intrinsically safe signals from Ex areas, with users who need to connect a smaller number of signals using the IP67 isolating transducers and isolating switching amplifiers in the IMC product series.

Your Benefits

- Time-saving as it can be used directly in the field without protective housing

- High level of safety thanks to mounting in Zone 2 in the immediate vicinity of machines or plants

- Simple and failsafe wiring via M12 connection

- The only integrated IP67 solution for Ex areas on the market

The connection can be made directly to a TBEN I/O station via ready-made cables with M12 connectors. This ensures a simple and safe connection, even under harsh operating conditions. Intrinsically safe signals are usually transmitted from Ex Zone 0 or 1. The IMC modules can be mounted directly in Zone 2 so as to enable installation at machine or plant level. This reduces the distance to the Ex equipment and therefore the negative influence of the cabling on the Ex circuit calculation.

Complete IIoT ecosystem for Zone 2

As almost the entire IIoT ecosystem is offered in TBEN-L and TBEN-S designs, users can also implement safety, RFID, IO-Link or control solutions (even including cloud connection) directly in Zone 2 without a control cabinet. To use the I/O solutions in Zone 2, users must also mount protective housings TBSG-L, TBSG-S or IMC-SG. These protect against impacts and sparks caused by unintended detachment of the cables. FM approved applications may also be run without the housings.

Decentralized control of Ex applications

With the ARGEE logic software on the TBEN modules, applications can be independently controlled directly in Zone 2. This is particularly useful for retrofit applications, as existing control systems do not have to be adjusted. Condition monitoring and data analysis via cloud systems are now also possible from Zone 2 without a control cabinet.

excom remote I/O for high-availability plants

The high-availability I/O system excom is well suited to applications with a large number of input and output signals, for example in large chemical or petrochemical plants. The remote I/O station is installed at plant level in a safe on-site protective box with protection class IP67.

- Automotive

- Modular Flexibility and Safety in Filter Production

- Cable with Integrated Current Monitoring Prevents Unwanted Shutdown of Conveying System

- Inductive Couplers Ensure Precise Material Feed

- Assembly Management with a Direct MES Connection

- Body Detection in Automobile Production

- Reliable Skid Detection in Automotive Production

- Error-free JIS Order Picking for Bumpers

- Laser Sensor Detects Shiny Sheet Metal Cylinders in Battery Production

- RFID Bus Mode Ensures Quality of Lithium-Ion Batteries

- Level Measurement in Dip Coating Line

- Level Control in Central Lubrication System

- Quality Assurance on the Gluing Robot

- Tilt angle sensor accelerates platform alignment

- Motor Control with Condition Monitoring

- IP67 Hybrid Module Processes Safety Signals

- Decentralized monitoring of cooling stations

- Robot welding cells networked with Ethernet

- Monitoring the cooling circuit on welding clamps

- Flow monitoring in drum washers

- Sheet Metal Thickness Measurement

- Condition Monitoring of Motors

- Cloud-based level monitoring

- Press Shop – Tool Identification

- Body Shop – Welding Nut Detection

- Paint Shop – Skid Identification

- Final Assembly – Robot Assembly

- Powertrain – Contactless Verification

- Area Guarding for Robotic Cells

- Item-level Detection with UHF RFID

- Supply of cooling lubricant in machine tools

- Controlling hydraulic pressure in pressing plants

- Measuring process pressure on scissor lifts

- Inspection of Tips on a Welder

- Manual Feeding in Weld Cell

- Detecting Black Parts on Black Door Panel

- Moonroof Clear Glass Detection

- Long-Range Inspection in Automotive Assembly

- Rubber Washer Detection on Engine Block

- Engine Block Part-In-Place Detection

- Electric Vehicle Detection in Charging Station

- Vehicle Detection in a Self-Serve Car Wash

- SUCCESS STORIES

- RFID Solution for Data Acquisition in Stator Production

- Modular Plant for Flexible and Efficient Production

- Laser Sensor Detects Black Bumpers in Assembly Cell

- Decentralized Safety Technology for Modular Production

- Modular Conveyor System

- RFID and I/O Modules for Safe Tool Changes

- RFID Guides AGV in Suspension Production

- IO-Link Wired Silencer Production

- Workpiece Carrier Identification in Rear Vent Production

- Weld Nut Sensing

- RFID Traceability

- RFID in Engine Production

- Bumper Production with Identification

- Solutions for Paint Shops

- Welding and Assembly Sensors

- Angle Sensors for Assembly Systems

- Tool Identification

- Pick-to-Light for Bumper Assembly

- RFID Identification of Injector Nozzles

- RFID in the Body Shop

- IO-Link Eases Differential Gear Production

- Ply Orientation Inspection

- Chemical

- excom I/O System Enables Safe Hydrogen Liquefaction

- Decentralized Automation in Ex Areas

- RFID Control of Tube Connections in the Ex Area

- Ethernet Signal Connection in the I&C Room

- Ethernet-based Automation of Modular Skids

- Ex Isolation in Modular Process Plants

- Detection of Pigs

- Remote Tank Level Monitoring with DX70

- Remote Signal I/O

- Easy Connection of Field Devices

- Signal Processing with System I/O in the Control Cabinet

- Signal Separation with Interface Technology in the Control Cabinet

- Identification of Hose Connections

- Efficient Monitoring of Cabinets in the Field

- Monitoring of Quarter Turn Actuators

- Planning and Assembly of System Solutions

- Success Stories

- Control Cabinet Monitor for Transmission of Condition Data

- Efficient Cooling of Industrial Furnaces with Turck's FS+ Flow Sensors

- I/O System Excom Creates Space in the I&C Rooms

- Zone 2 and 22 RFID

- Efficient Testing Control

- Intrinsically Safe Field Communication

- Process Control System Partnership

- Hazardous Area Remote I/O

- Dual Valve Position Feedback

- Flexibility with Fieldbus

- Asset Management with Remote I/O

- Correct Positioning with RFID in Carbide Production

- Fast conversion in restricted space

- Energy

- Capacitive Sensor Detects Point Level in Pellet Heating System

- RFID System Identifies Solar Cell Carriers

- Decentralized I/O System for Hazardous Areas at H2 Refueling Stations

- Decentralized I/O Solution in Ex Zone for H2-Fueling Station

- I/O Module Facilitates Setup and Mobile Use of Fuel Cell Test Stand

- Wind Turbine Rotor Positioning

- IP67 I/O in Coal Production

- UHF RFID Identifies Switch Gear

- Remote I/O in Biogas Plant

- Food and Beverage

- RFID Tracking Reduces Food Waste in Ice Cream Production

- Dough Height Inspection for Accurate Measurement

- Condition Monitoring Sensor Automates Climate Control

- Condition Monitoring of Control Cabinets

- Condition Monitoring in Storage Rooms

- Dough Thickness Control in Rolling Machines

- Leading Edge Detection of Plastic Container

- Identification of Food Containers

- Container Check

- Date/Lot Code Verification

- Detection of Valve Position

- Detection of Pipe Elbows

- Identification of Chocolate Moulds

- Barcode Reading on Depalletizer Station

- Success Stories

- Cloud-based Maintenance for Steam Generators

- RFID Support Enables Track and Trace in Food Production

- Grist for the Mill

- Decentralized Control Modules in Coldstore

- Track and Trace in Meat Production with RFID

- Contact-free Encoder in Potato Production

- UHF RFID in Food Distribution Center

- RFID for Chocolate production

- Distributed I/O for Food Equipment

- Remote I/O for Distilleries

- RFID and Autoclaves

- Transparency in Chocolate Manufacturing

- IP67 Power Supplies for Conveyors

- Identification in Food Product Storage

- Detecting Refrigerated Breakfast Rolls on a Multi-Lane Conveyor

- Reliable Cap Orientation Verification in Aseptic Areas

- Clear and Tipped Bottle Detection on Depalletizer

- Clear Plastic Bottle Detection

- Frozen Food Packaging Label Inspection

- In-Line Bottle Accumulation on Single Filer

- Logistics

- UHF RFID Tunnel for Goods Identification on Conveyor Belts

- Preventing Package Jams in the Logistics Center

- Height Control and 3D Spatial Monitoring on Autonomous Forklift Trucks

- Decentralized Control of Conveyor Modules

- Tracking Big Bags with RFID

- Distance Detection in Container Cranes

- Access Control for Protected Areas

- Decentralized Muting of Electro-sensitive Protectice Equipment

- I/O Blocks Control Roller Conveyor Modules

- Container Check

- Fast Tag Detection at Warehouse Gates

- Item-level Detection with UHF RFID

- Preventive Maintenance on Conveyor Belts

- Detection of Transport Containers

- Level Detection in Vessels

- Identification of Cryovessels

- Identification of Mobile Containers with Handheld Devices

- Identification of Food Containers

- Tier 1 – Bumper Identification

- Condition Monitoring in Storage Rooms

- Collision Protection on Reach Stackers

- Success Stories

- Efficient Solution for the Digitalization of Conveyor Technology

- Logistics: RFID Reduces Error Quota by 99 Percent

- ROI After Three Avoided Delivery Errors

- Reliable AGV Control through Sensor-based Complete Solution

- Sustainable Tracking of RTIs thanks to RFID

- RFID Solution for Error-Proof Material Logistics

- RFID with HF Bus Mode Eases Seed Storage

- Pick-by-Light accelerates manual logistics by over 60 percent

- Pick-by-light Solution Facilitates Assembly Processes

- RFID Enables Unmanned Store at Major Building Site

- I/O and Safety Modules Increase Throughput in Intralogistics

- Shipment Tracking for Raw Materials

- RFID-Based Tracking Solution for Loading Error Minimization

- RFID-based Tracking of Inbound and Outbound Materials

- Decentralised UHF RFID Solution

- Contact-free Encoder in Potato Production

- Decentralized Control Modules in Coldstore

- Speed Control via Radar Sensor QT50

- IP67 Power Supplies for Conveyors

- Modular Conveyor System

- RFID Solution for Warehouse

- RFID Guides AGV in Suspension Production

- RFID Identifies Pharmaceuticals

- UHF RFID in Food Distribution Center

- Autonomous Parking Assistance for Trucks

- Mobile Equipment

- Animal and Object Detection on the Combine Harvester

- Condition Monitoring Sensor Automates Climate Control

- Loading Dock Occupancy Monitoring

- Monitoring Railcars Wheels Wirelessly

- Automatic Slope Compensation

- Distribution Lines for Field Sprayers

- Reach Stacker Status With Bright Lighting Indicators

- Angle Measurement on a Field Sprayer

- Material Flow Monitoring on a Combine Harvester

- Determining the Boom Angle Position

- Vehicle at Loading Dock

- Wireless Forklift Signaling

- Equipment Compartment Illumination on Fire Engines

- Two-Axis Tilt Measurement on a Combine Harvester

- Collision Protection on Reach Stackers

- Success Stories

- RFID Solution with Smart Forklifts in Autombile Production

- Safe Remote Maintenance of Irrigation and Drainage Pumps

- Access Control with RFID System

- Selective Asparagus Harvester

- Position Measurement with RFID and Encoder

- Speed Control via Radar Sensor QT50

- RFID Guides AGV in Suspension Production

- Block I/O Modules on Super Yacht

- Wear-free Encoder on Hopper Dredger

- I/O for Dust Suppression

- Cabinet Cooling

- Quick Disconnect Connectivity

- Automation Solutions for Extreme Cold

- Remote I/O for Cranes

- Rugged Heavy Metal Lifting

- Rollercoaster Positioning

- Mobile Machinery Solutions

- Exact Height Positioning

- Critical Angle Sensing

- Predictive Maintenance of Machine Parts at Port-Based Coal Conveying Facility

- Angle Sensor Detects Platform Lift

- Oil and Gas

- Packaging

- Decentralized RFID Package Verification

- Identification of Printing Color Cartridges

- Reliable Operation of Machines

- Monitoring of Caps in Filling Lines

- Monitoring Changeover Processes

- Identification of Test Bottles

- Box Insert Detection

- Level Monitoring of Ground Coffee

- Level Detection in Vessels

- Carton Dimensioning

- Detection of Transport Containers

- Success Stories

- Clear Container Detection

- Correct Label Verification

- Detecting Different Size Packages on a Conveyor

- High-Speed 2D Barcode Inspection

- Multicolored Reflective Package Detection

- Plastic Roll Diameter Measurement

- Tube Positioning Using a Registration Mark

- Vertical Form Fill Seal Machine Solutions

- Pharma

- End-to-End Sample Tracking with RFID

- RFID Control of Tube Connections in the Ex Area

- Decentralized package verification for pharmaceutical products

- Automate Modular Skids

- High-Speed Tablet Counting With Fiber Amplifier

- Pharmaceutical Skids with Decentralized I/O Technology

- Ex Isolation in Modular Process Plants

- Control of Valve Interfaces

- I.V. Bag Liquid Detection

- Monitoring of Quarter Turn Actuators

- Detection of Pipe Elbows

- Remote Signal I/O

- Liquid Level Monitoring In A Large Tank

- Planning and Construction of Super Skids

- Easy Connection of Field Devices

- Identification of Cryovessels

- Identification of Mobile Containers

- Identification of Mobile Containers with Handheld Devices

- Identification of Hose Connections for Precursors

- Identification of Hose Connections in Sterile Areas

- Identification of Hose Connections in Ex Zone 1

- Identification of Big Bags and Bioreactors

- Identification of Single-Use Applications

- Semiconductor

- Electronic Marking Verification

- Counting Integrated Circuits

- Inspection of Two Barcodes

- Compact Safety Control

- Safeguarding Small Access Points

- Semiconductor Process Tool Illumination

- Adhesive Detection on PCB Assembly

- Wafer Center Detection with DF-G2

- Great Detail Inspection for Mobile Electronic Devices

- Error Proofing for IC Chips loaded into Pocket Tape

- Presence and Orientation of IC Chips Seated in Nests

- Detection of Hard Disks

- Multiproduct Light-Guided Assembly Station

- LED Status Indication During Semiconductor Manufacturing

- Safeguarding Small Access Points

- Success Stories

-turck-image.jpg)

-turck-thumbnail.jpg)