Applications

Cloud-based Remote Machine Maintenance

Special machine manufacturer Velco uses a remote monitoring solution based on Turck Cloud Solutions for locating error sources and monitoring production parameters

Cloud-based level monitoring

Battery-powered ultrasonic sensors wirelessly transmit data on lubricant levels to the Cloud

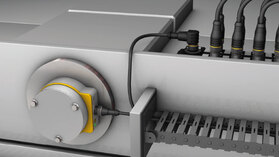

Fast Tag Detection at Warehouse Gates

Multiplex operation with external antennas on RFID UHF read/write head Q300

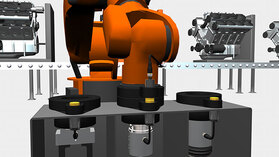

Tool Identification with RFID

Turck's BL ident RFID system reduces the reading time for the tool turret of a CNC machine from 130 to 10 seconds

Challenge tool changer

Many applications require that parts of a machine are changed to accommodate different phases in the production cycle.Efficient Monitoring of Cabinets in the Field

Monitoring the condition of cabinets and other housings in the field can be difficult. Generally, several separate sensors and connections are needed in the housing. A clever and compact alternative is Turck’s cabinet guard IMX12-CCM.

Identification of Cryovessels

The BL ident RFID system from Turck enables clear and seamless monitoring during transportation and storage.

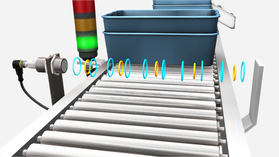

Recording the Swivel Movement of a Core Shooter

Short cycle times are particularly important when manufacturing sand cores for metal casting using core shooters. The swivel movement of the core carrier, which is recorded by the contactless IO-Link encoder QR24-IOL from Turck, has a major influence on the clock rate of the machine.

RFID Identifies Pharmaceuticals

Together with other partners, Turck Korea has implemented a complete serialization and identification system for pharmaceutical products – from the production plant to the dispatch warehouse

Exact Height Positioning

In its Flying Fish roundabout ride, Zierer Karussell- und Spezialmaschinenbau GmbH previously measured the horizontal position of the gondola arms using individual proximity switches.

- Technologies

- Asset Monitoring Gateway with Cloud ID

- Asset Monitoring Gateway with SNAP ID

- Codesys

- Condition Monitoring

- Ethernet in Hazardous Locations

- Field Logic Controller

- Industrial Cloud

- Industry 4.0

- IO-Link

- Machine Safety

- Modular Machines

- Module Type Package

- Multiprotocol Ethernet

- Pick-to-Light

- Profinet

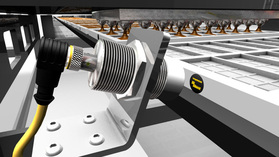

- RFID

- Snap Signal

- Sustainability

- TAS – IIoT Service Platform

- The Visual Factory